Liquids & Gas Processing

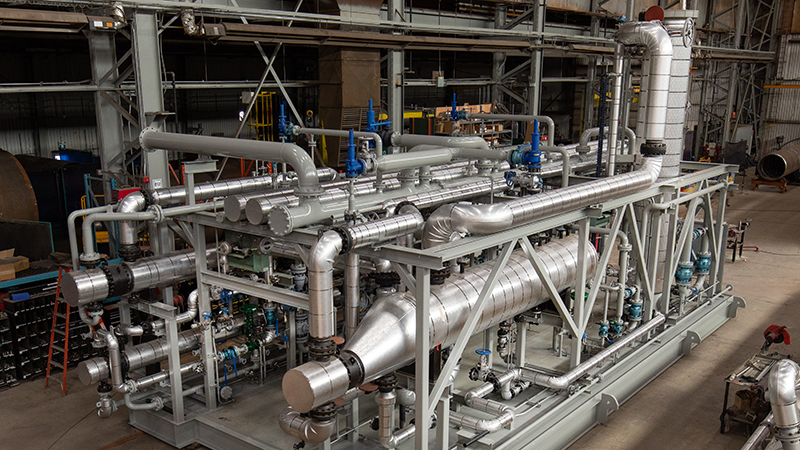

Startec provides a multitude of gas processing solutions.

We design and build amine systems, distillation towers, multiphase separators, heat recovery, and gas treating equipment. Our products include vapor compression systems using refrigerants such as ammonia, CO2, propane, and others, absorption systems, or expansion of compressed gases.

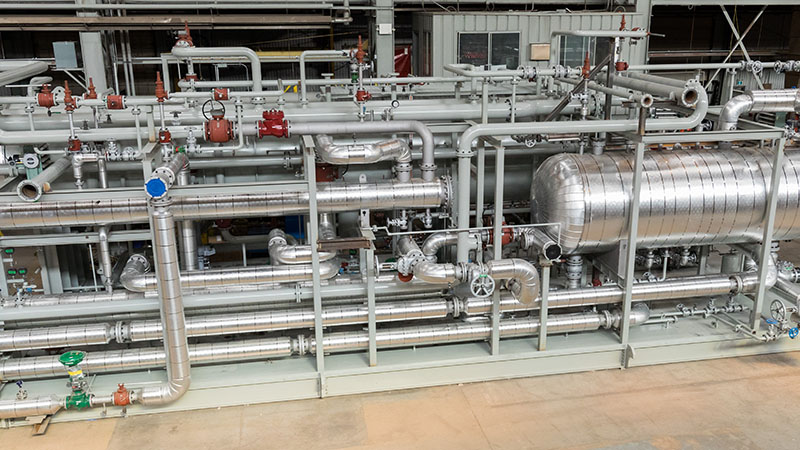

Amine Sweetening

Our amine sweetening units utilize liquid solvents to remove acid gases (CO2 and H2S) from natural gas. This regenerative solvent requires heat to release a concentrated stream of acid gas that can be further processed or reinjected. Based on the application, we can design the process to maximize CO2 slip or enhance CO2 removal.

With a variety of available solvents, Startec will provide the most economical sweetening solution for your project and business.

Our amine units are capable of 1 – 400 MMSCFD with rates ranging from 30 – over 1,600 GPM. Our amine is achievable of less than 4.0ppm H2S, and less than 2.0mol% CO2 outlet gas.

Solvent technologies include DEA, MDEA, DGA, Mixed Amines, Proprietary Amines, Sulfinol, and Selexol.

Fuel Gas Conditioning

Fuel gas treatment for engines or turbines is a crucial process for optimizing efficiency and extending operating life.

Startec provides the correct treatment & filtration of gas to meet optimal fuel gas quality for your application needs, with capacities from 0.25 – 50 MMSCFD.

Dehydration

T.E.G. Dehydration

Startec provides a liquid desiccant T.E.G. system for the removal of water from natural gas to meet pipeline specifications.

Startec's standard sweet and sour designs range from 30 – 50 MMSCFD, capable of 1 – 400 MMSCFD with operating pressures of 150 – 1,400 PSIG. Startec offers custom designs as well.

E.G. Dehydration

Startec regularly manufactures E.G. dehydration systems as part of our mechanical refrigeration gas plants. Our standard E.G. packages range from 1.5 – 20.0 GPM, capable of 20 – 600 MMSCFD.

Startec's proven technology and meticulous design cut E.G. injection rates in half.

Molecular Sieve Dehydration

Startec's molecular sieve units provide maximum water removal from natural gas, allowing it to be processed at cryogenic temperatures (less than -100°F), with standard designs capable of 20 – 600 MMSCFD.

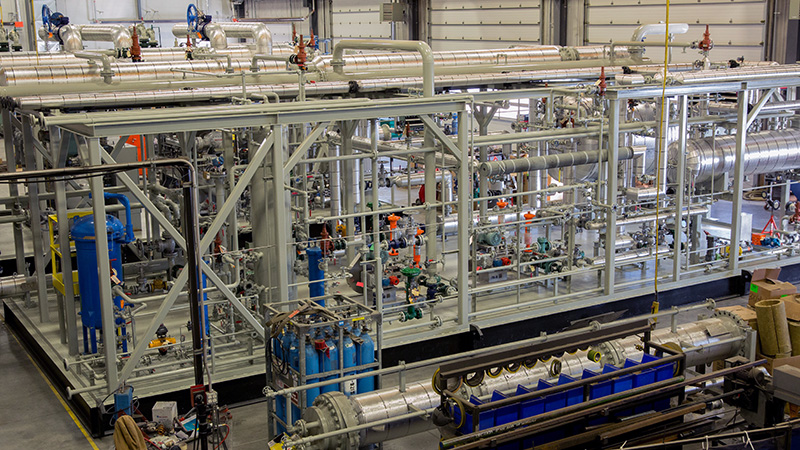

Refrigeration

Refrigeration is a foundational product offering at Startec, ranging from 10 – 2,500+ tonnes, with natural gas plant capabilities from 1 – 400 MMSCFD. Known for our pioneering way, we continue to perfect cooling methods for a myriad of industries including natural gas processing, petrochemical, refining industrial gas, and others.

Startec packages Mycom, Howden and Ariel products for your rotary screw, reciprocating, or centrifugal application and are a proud OEM of Frick products.

Whether your challenge is small or large, you can trust Startec to find a better solution.

Dew Point Control

Startec's dew point control packages process natural gas for pipeline transmission. Either Joule Thomson or mechanical refrigeration applications do this by condensing out the heavier hydrocarbons from the gas and bring the quality of the natural gas to the project's pipeline specifications.

Our mechanical offerings use a refrigeration loop to cool natural gas, again dropping out the heavy hydrocarbons and ensuring gas meets the pipeline specifications.

These hydrocarbon liquid dropouts add another revenue stream for your business and create more value for your project.

Startec's dew point control designs are capable of 1 – 400 MMSCFD, with pressures ranging from 150 PSIG – 1,300 PSIG.

Liquid Recovery

For maximum NGL recoveries, Startec has a variety of solutions to meet your needs including reciprocating, liquid ring, rotary, screw, and vane. We offer cold mechanical refrigeration (-40°C), a combined mechanical refrigeration and J.T. unit, and turbo expander deep cut packages. These packages are capable of 10 – 400 MMSCFD. Our team of Everyday Mavericks is confident in creating fit-for-purpose (small or large scale) applications ranging from 1 – 15 MMSCFD.

Stabilization

From production well condensate to pipeline condensate, Startec has an energy-efficient stabilizer design – capable of 250 – 60,000 bbl/day – that will process your liquids to meet pipeline C5+ specifications. Trouble with paraffinic condensate? Startec stabilizers are designed to reduce fouling through the elimination of wax precipitation.

Fractionation

Startec proudly offers standard fractionation designs for de-ethanizers, depropranizers, and debutanizers with fully customizable options to ensure your project can access various types of transportation. Specializing in modular designs, these units are capable of up to 120,000 bbl/day output, with all stacking completed in house.

Offerings include:

- Inlet Liquid Stabilizers (C5+)

- Demethanizers (C2+)

- De-ethanizers (Ethane & C3+)

- Depropanizers (Propane C3 LPG)

- Debutanizers (Butane C4 LPG)

- Butane Splitter (i-C4, n-64 LPG)

- Condensate Stabilizers

- Refrigerated Reflux Systems

- Custody Transfer Meter Skids

Sour Water Strippers

Sour water must be expertly processed and sweetened in a sour water stripper to be disposed of or reused. Startec’s sour water strippers remove hydrogen sulfide and ammonia from sour water generated in industrial processes like fracking, refining, and more. Startec has the expertise and technology for your sour water treating needs with capabilities from 1,000 – 50,000 bbl/day.